Tool Balancer Overview: Revolutionizing Industrial Efficiency

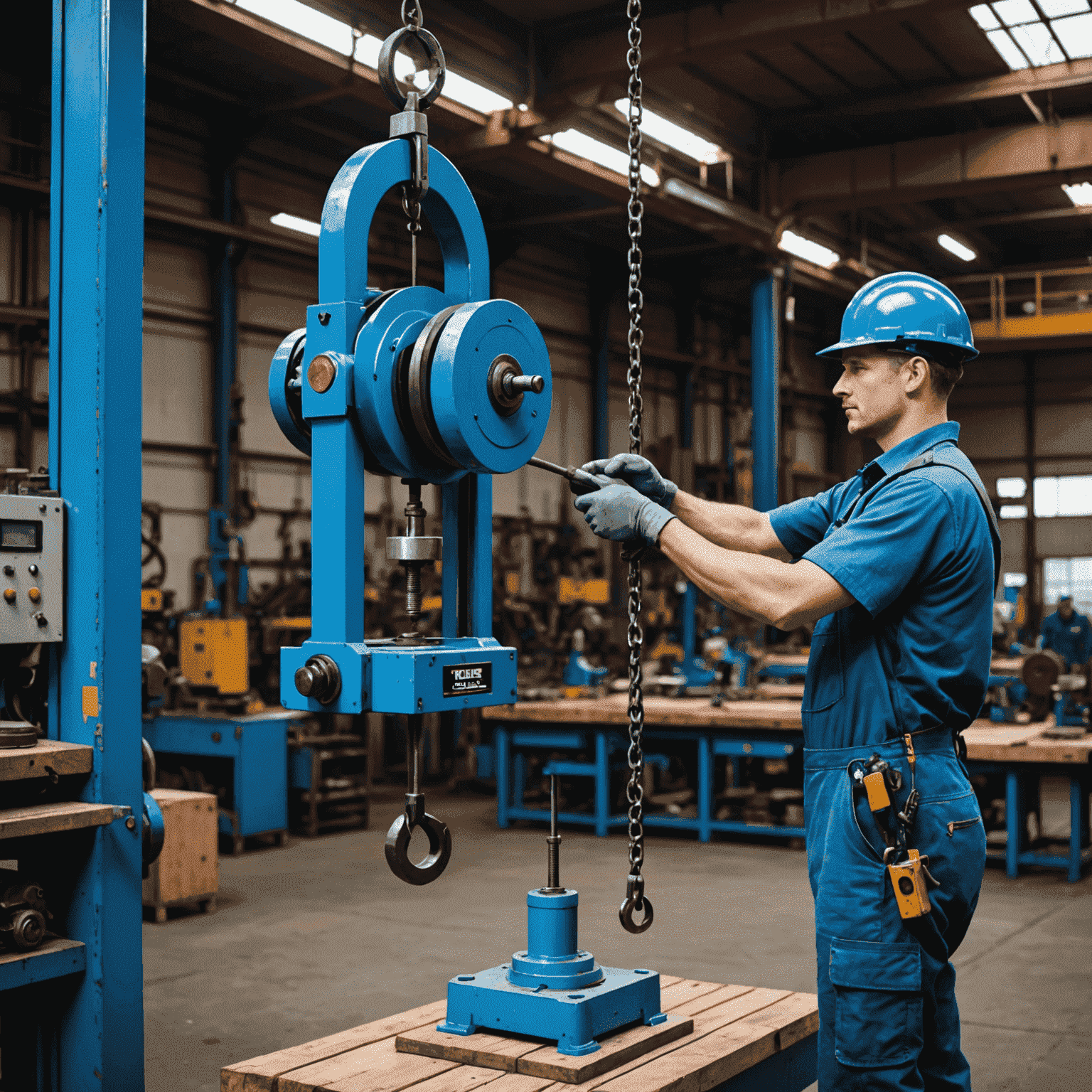

Tool balancers are innovative devices designed to enhance productivity and ergonomics in industrial settings. These mechanical marvels, like our flagship Balancer YBF-130L, are transforming workplaces by making heavy tool handling a breeze.

What is a Tool Balancer?

A tool balancer, also known as an industrial balancer or spring balancer, is a mechanical device that suspends tools or equipment, counterbalancing their weight to allow effortless manipulation by workers. The Balancer YBF-130L, for instance, exemplifies the pinnacle of this technology, offering unparalleled support for heavy tools on production lines and in workshops.

Enhanced Productivity

By eliminating the strain of tool weight, workers can focus on precision and speed, significantly boosting overall productivity.

Improved Ergonomics

Tool balancers reduce physical stress and fatigue, promoting better posture and reducing the risk of work-related injuries.

Versatile Applications

From assembly lines to construction sites, tool balancers like the YBF-130L adapt to various industrial environments and tool types.

The Balancer YBF-130L: A Game-Changer in Tool Handling

- Superior load capacity for heavy-duty tools

- Precision balance adjustment for various tool weights

- Durable construction for long-lasting performance

- Easy installation and maintenance

- Enhanced safety features for secure operation

Industries Benefiting from Tool Balancers

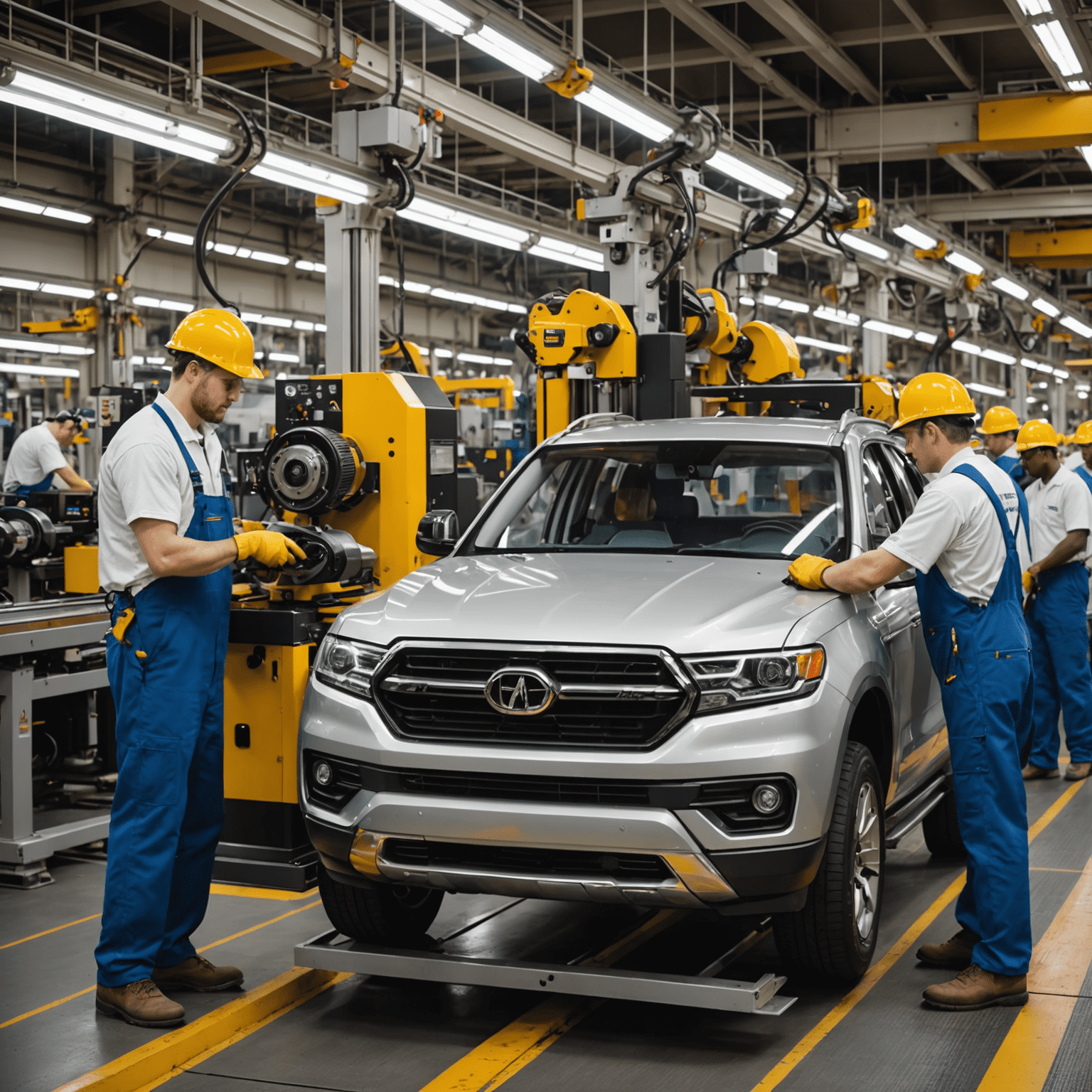

Automotive Manufacturing

Streamlining assembly processes and improving worker comfort during vehicle production.

Aerospace Industry

Enhancing precision and safety when working with sensitive aircraft components.

Construction

Improving on-site efficiency and reducing worker fatigue during building projects.

The Future of Industrial Efficiency

As industries continue to evolve, tool balancers like the YBF-130L are becoming indispensable assets in the pursuit of enhanced productivity, worker safety, and operational excellence. By investing in these innovative solutions, businesses can stay ahead of the curve and create more efficient, ergonomic workplaces for their employees.